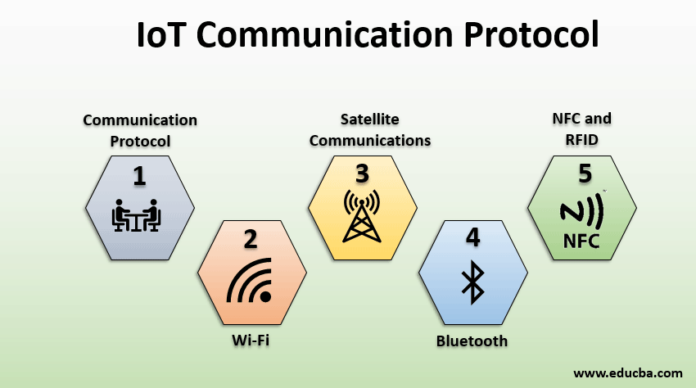

Communication protocols enable data exchange between devices in industrial automation systems. Each protocol is designed to serve specific needs like real-time communication, scalability, or compatibility with specific devices. Here’s an overview of some widely used industrial communication protocols:

1. Modbus

Overview:

Modbus is a simple, open-source, and widely adopted protocol used for communication between industrial devices.

- Developed by: Modicon (now Schneider Electric) in 1979.

- Communication Type: Master-slave (now often called client-server).

- Transport Mediums:

- Modbus RTU: Runs over serial communication (RS-232, RS-485).

- Modbus TCP/IP: Runs over Ethernet networks.

Features:

- Easy to implement and widely supported by devices.

- Uses simple commands to read/write registers, coils, and discrete inputs.

- Limited to transmitting process data (e.g., no advanced features like security or metadata).

Use Cases:

- Connecting PLCs, RTUs, and sensors in smaller systems.

- Simple process control and monitoring tasks.

2. OPC UA (Open Platform Communications Unified Architecture)

Overview:

OPC UA is a platform-independent, service-oriented protocol for secure and standardized communication between devices and systems.

- Developed by: OPC Foundation.

- Communication Type: Client-server and publish-subscribe.

- Transport Mediums: TCP/IP, HTTP, HTTPS.

Features:

- Interoperability: Works across devices from different manufacturers.

- Security: Includes encryption, authentication, and data integrity checks.

- Scalability: Supports small devices to enterprise systems.

- Data Modeling: Rich semantic modeling for complex data types and metadata.

Use Cases:

- Integration between SCADA, MES, and ERP systems.

- Secure communication in Industry 4.0 and IoT applications.

3. MQTT (Message Queuing Telemetry Transport)

Overview:

MQTT is a lightweight, publish-subscribe messaging protocol optimized for low-bandwidth, high-latency, and unreliable networks.

- Developed by: IBM in the late 1990s.

- Communication Type: Publish-subscribe (broker-based).

- Transport Medium: TCP/IP.

Features:

- Lightweight: Minimal overhead, ideal for resource-constrained devices.

- Publish-Subscribe Model: Devices publish data to a broker, and other devices subscribe to topics of interest.

- Scalability: Supports thousands of devices.

- Quality of Service (QoS): Offers three levels of message delivery assurance.

Use Cases:

- Industrial IoT (IIoT) applications.

- Connecting sensors to cloud platforms (e.g., AWS IoT, Azure IoT Hub).

- Monitoring remote equipment.

4. Profinet (Process Field Network)

Overview:

Profinet is a real-time, Ethernet-based communication protocol designed for industrial automation and process control.

- Developed by: PROFIBUS & PROFINET International (PI).

- Communication Type: Master-slave or peer-to-peer.

- Transport Medium: Ethernet.

Features:

- Real-Time Communication: Supports deterministic data exchange for time-critical applications.

- Scalability: Works with small to large industrial networks.

- Integration: Easily integrates with field devices, including legacy PROFIBUS devices.

- Diagnostics: Built-in tools for network and device diagnostics.

Use Cases:

- Motion control in manufacturing.

- High-speed communication in robotic systems.

- Integration of field devices with PLCs.

5. EtherNet/IP (Ethernet Industrial Protocol)

Overview:

EtherNet/IP is an Ethernet-based protocol designed for industrial automation, offering a standard method to connect and control devices.

- Developed by: Rockwell Automation and managed by ODVA (Open DeviceNet Vendors Association).

- Communication Type: Master-slave or peer-to-peer.

- Transport Medium: Ethernet.

Features:

- CIP (Common Industrial Protocol): EtherNet/IP is built on CIP, enabling seamless integration with other CIP-based protocols like DeviceNet and ControlNet.

- Real-Time Communication: Includes time-critical control and standard TCP/IP communication.

- Scalability: Suitable for small to large systems.

- Flexibility: Works with commercial off-the-shelf Ethernet hardware.

Use Cases:

- Factory automation, especially in systems using Rockwell/Allen-Bradley devices.

- Process control in oil, gas, and water treatment facilities.

6. Comparison of the Protocols

| Protocol | Primary Use | Strengths | Challenges |

|---|---|---|---|

| Modbus | Basic data exchange in small systems. | Simple, widely supported. | Limited security, slower speeds. |

| OPC UA | Interoperable, secure data sharing. | Rich data modeling, security, scalability. | Higher complexity to implement. |

| MQTT | IoT and cloud connectivity. | Lightweight, scalable QoS levels. | Broker dependency is less suited for real-time control. |

| Profinet | High-speed industrial networks. | Real-time control and diagnostics. | Ethernet-based can be expensive. |

| EtherNet/IP | Ethernet-based factory automation. | Compatibility with commercial Ethernet. | Requires robust Ethernet networks. |

How These Protocols Facilitate Data Exchange

-

Interoperability:

- Protocols like OPC UA enable devices from different manufacturers to communicate seamlessly.

-

Real-Time Control:

- Profinet and EtherNet/IP provide deterministic communication for applications like motion control and robotics.

-

IoT Integration:

- MQTT is ideal for transmitting sensor data to cloud platforms and IoT dashboards for advanced analytics.

-

Scalability:

- Protocols like OPC UA and MQTT are scalable for systems ranging from small IoT devices to enterprise-level deployments.

-

Ease of Diagnostics:

- Profinet and EtherNet/IP offer built-in diagnostics to quickly identify and troubleshoot issues in the network.

By choosing the right communication protocol based on the system requirements, industrial environments can achieve efficient, reliable, and secure data exchange, forming the foundation of modern automation and IoT systems.