Automated systems like PLCs (Programmable Logic Controllers) and DCS (Distributed Control Systems) are designed to control industrial processes with minimal human intervention by continuously monitoring, analyzing, and executing control strategies based on predefined logic. They enable efficiency, precision, and consistency in industrial operations. Here’s an explanation of how these systems work:

1. Key Components of Automated Systems

Automated control systems generally consist of:

- Input Devices: Sensors and instruments (e.g., temperature, pressure, flow sensors) that collect data about the process.

- Control System:

- PLC: A robust, programmable device that executes sequential and discrete control tasks.

- DCS: A centralized system for complex, continuous processes where tasks are distributed across multiple controllers.

- Output Devices: Actuators (e.g., motors, valves, relays) that physically execute commands.

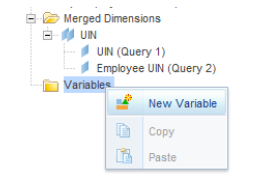

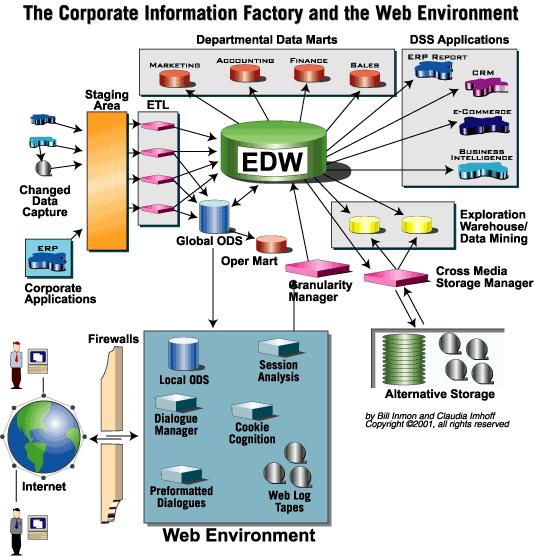

- HMI/SCADA Interface: Human-Machine Interface (HMI) or SCADA systems provide visualization, monitoring, and control capabilities for operators.

- Communication Networks: Enable data exchange between sensors, controllers, and actuators.

2. How Automated Systems Work

Step-by-Step Process

- Data Collection:

- Sensors installed throughout the industrial process measure critical parameters like temperature, pressure, flow rate, and machine status.

- These inputs are sent to the controller (PLC or DCS).

- Processing and Analysis:

- The controller reads sensor data in real-time and compares it against setpoints or pre-programmed thresholds (e.g., maintain temperature at 200°C).

- Control logic, written as programs or algorithms, determines the necessary actions (e.g., increase flow, reduce pressure).

- Decision Making:

- Based on the control logic, the controller decides the appropriate action to maintain optimal process conditions or achieve desired outcomes.

- Execution of Commands:

- The controller sends commands to actuators, which adjust the process accordingly (e.g., open a valve, stop a conveyor belt, increase motor speed).

- These commands are executed precisely, ensuring the process remains within the desired limits.

- Feedback Loop:

- A continuous feedback loop is maintained where sensors provide updated data to the controller after actions are executed.

- This ensures that any deviations from the setpoint are corrected automatically.

3. Comparison of PLC and DCS Control

Both PLCs and DCS serve as control systems, but their applications differ based on the complexity and scale of the process:

| Feature | PLC | DCS |

|---|---|---|

| Primary Use | Discrete or sequential control (e.g., packaging lines, assembly). | Continuous and batch processes (e.g., oil refining, chemical production). |

| Control Strategy | Centralized control of smaller systems. | Decentralized, distributed control of large-scale processes. |

| Flexibility | Highly customizable and suitable for modular tasks. | Suited for integrated and complex systems. |

| Response Time | Fast response time for high-speed operations. | Ideal for slower, continuous processes. |

4. Benefits of Automated Systems

-

Minimal Human Intervention:

- Once programmed, PLCs and DCS can execute tasks automatically without the need for constant operator involvement.

- Human intervention is limited to setup, monitoring, and occasional troubleshooting.

-

Efficiency:

- Processes operate continuously and consistently, leading to higher productivity.

- Downtime and delays caused by manual operations are reduced.

-

Precision and Consistency:

- Automated systems maintain tight control over parameters like temperature, flow, and pressure, ensuring uniform quality of products.

-

Safety:

- Automated systems quickly respond to alarms or deviations to prevent accidents.

- They can shut down processes in case of emergencies.

-

Scalability:

- New sensors, actuators, and logic can be easily added to accommodate process changes or expansions.

-

Cost Reduction:

- Reduced need for manual labor and minimized energy waste lead to long-term cost savings.

5. Real-World Examples

-

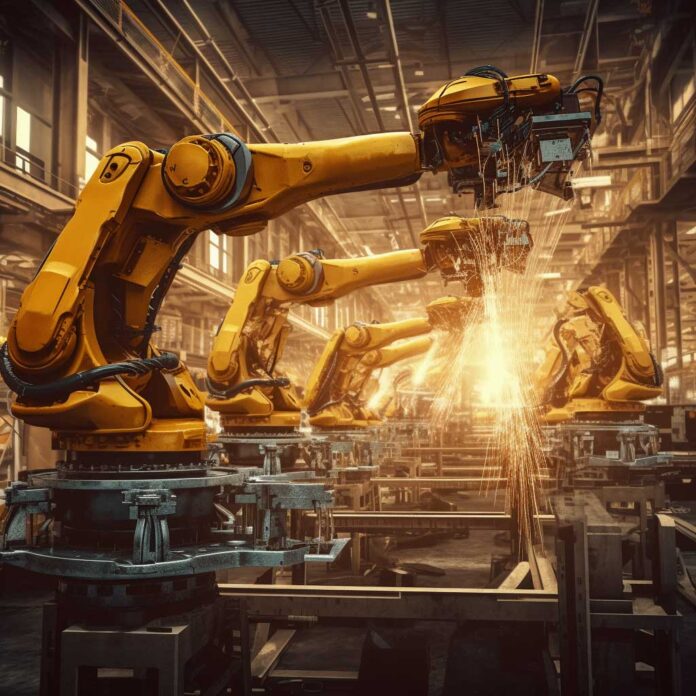

Manufacturing:

- PLC: Controls conveyor belts, robotic arms, and sorting mechanisms in a car manufacturing plant.

- Example: If a sensor detects an improperly assembled product, the PLC diverts it from the production line.

-

Oil Refining:

- DCS: Continuously monitors and adjusts the chemical reaction conditions in a distillation column.

- Example: If the pressure rises beyond safe levels, the DCS automatically adjusts valve positions to release excess pressure.

-

Water Treatment:

- A combination of PLCs and DCS controls pumps, chemical dosing systems, and filtration units to ensure consistent water quality.

6. Key Technologies Enabling Automation

- PID Controllers: For fine-tuned control of variables like temperature or pressure.

- Communication Protocols: Enable real-time data exchange (e.g., Modbus, OPC UA, EtherNet/IP).

- SCADA Integration: SCADA systems provide centralized monitoring and remote control of multiple PLCs and DCS units.

Summary

Automated systems like PLCs and DCS operate by gathering sensor data, analyzing it based on pre-programmed logic, and issuing commands to actuators to maintain or adjust process parameters. By doing so, they minimize human intervention, improve efficiency, ensure consistency, and enhance safety in industrial processes. These systems form the backbone of modern industrial automation.